|

Back to Features Page By, EZ Rhino |

|||||||||||

|

Exhaust Routing

Working Out The Bugs

As with all projects of this scope, there were a few glitches to work on. Torque Converter lockup was the first. This one was an easy problem to fix, but took a long time to diagnose. For those of you who don't know, a 700r4 is a four speed transmission with a torque converter lockup in overdrive (fourth gear). (Incidentally, it will also lockup in third if you manually shift it into third). Lockup means that the torque converter will "lock" for a 1:1 ratio with the engine, in other words, it won't slip. It is very important for this type of transmission to lock up like it's supposed to or you will prematurely burn it up. When I first got mine going, I couldn't feel the lockup (It feels as if it's shifting into another gear while doing so). Also, my transmission temperature gauge showed that the transmission was running very hot. I thought this was funny for normal around-town driving. Luckily I have a neighbor that rebuilds transmissions. He told me to hook up my mechanical oil pressure gauge to my transmission cooler line. When the converter locks up the pressure will drop from 30 or so psi to 0. This trick confirmed that it wasn't locking up. Now, let me take a minute here to explain how the system works. I intended to exactly duplicate how the factory drivetrain functioned in the Blazer that it came from. The converter lockup is controlled by the ECM or the vehicle's computer. Howell's harness incorporated the four pin plug that plugs into the transmission and connects it to the computer. It is also necessary to have a VSS, or vehicle speed sensor. This screws into the speedometer cable and reads MPH, and sends a signal to the computer through the Howell harness. Finally, (and here's what I did wrong), a 12 volt hot wire needs to go to the transmission (via the Howell harness) through a brake switch. When you press on the brake, it will unlock the torque converter. It is important to get the factory GM brake switch. It's actually two switches in one....a normally open switch to run your brake lights, and a normally closed switch for the transmission. When I installed the switch, I didn't quite have it adjusted far enough to activate the transmission part of the switch. The brake lights worked, but not the transmission part. Once I figured that out, it was a 30 second adjustment and the system started working properly. There are other ways of solving the torque converter riddle. It's even possible to put a non-lockup converter in. The way I did it is how the system worked in the stock application. My second problem was a rich-running fuel delivery system. After a little driving, my check engine light kept coming on. A check of the fuel injection diagnosis manual that Howell provided with their harness told me the motor was running rich. A call to Troy at Howell yielded some suggestions. After a little work, I realized that the fuel return line back to the tank was restricted due to a dirty or no longer functioning roll-over valve. I eliminated this mess (you know the mess of rubber lines stuffed up in the driver side rear wheelwell? It's all a bunch of crap! Get rid of it.) and that solved the running rich problem.

There were some other smaller bugs to work out, too. Remember the reflective insulation I put on the firewall? It works really well. In fact, I can't even hear the engine or exhaust during normal driving. All I can hear are my noisy tires. Before the swap, all I could hear was the noisy engine. However- that aluminum heat shield on the firewall is (gasp!) conductive to electricity. Make sure you don't...umm...well....have any loose hot wires dangling anywhere, it will cause a short and may...umm....blow up two brand new coils...ugg! A compression check revealed low compression in three cylinders. Not so low to the point of poor performance, but it does cause my 350 to burn a lot of oil and smoke quite a bit. It looks like a rebuild is in the near future, but I'm not unhappy about this. Heck, I got it for $100, I can't really complain too much. I was concerned about not having some kind of gear indicator on the shifter, but after driving it around for the summer now, I'm totally used to it and don't feel that an indicator is necessary at all. Right when I thought all the bugs were worked out, my transfer case started making a lot of noise. Remember how I wanted to make sure that it didn't leak oil? So much for that idea...dang thing leaked from at least 5 places, but that will soon be cured as the rebuild nears completion. As of publishing, the transfer case has been completely rebuilt.

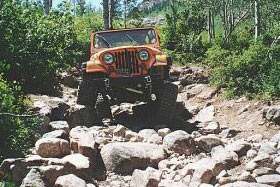

In conclusion, a V8 swap is one of the best things I've ever done to my jeep, right behind the suspension. The power is fantastic, the automatic is wonderful to drive, it crawls slower than before while in low range, and I have better control than with the manual transmission. It was SO much work, and a big headache at times, but also a very rewarding experience. I find it laughable when I read in the 4x4 magazines about how it takes thousands upon thousands of dollars to do a smog legal V8 swap, and how it's so expensive to find a good donor motor. Phooey! I could have done it even cheaper if I had really wanted to, but I am satisfied with my results. I place the cost of the swap under $2000 or so, give or take a little, and that includes everything. What would I have done differently? Not too much. Next time I may try for a Vortec V8, and getting a motor that is either recently rebuilt or rebuilding it before I put it in would be nice. But hey, I'm satisfied!

©

2000 Rockcrawler. All Rights Reserved

|

|||||||||||