|

|

|||||||||||||||||

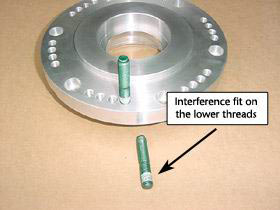

JB Conversions Rotation Plate Kit: Now that we've beefed up our Dana 300 extensively, it's time to use the Rotation Plate Kit from JB Conversions to allow us to rotate, or “clock” it, thereby increasing our over-center ground clearance. The kit is complete, with the rotation plate, longer input shaft, bolts, oil seal, and studs designed with an interference fit that keep them from backing out when the nut is removed. The kit comes standard with a 23 spline input shaft for Jeeps, but the input shaft is available in GM spline counts, as well.

While most clocking rings are a separate steel ring, the JB Conversions rotation plate is unique in that it is machined from a solid piece of billet aluminum that incorporates the stock Dana bearing retainer. The plate allows the transfer case to be rotated up 4 positions, in 7.5 degree increments. With the right combination of transmission (some, like my T-18, restrict how much you can rotate the t-case), and under body clearance, the JB Conversions Rotation Plate can allow you to run a completely flat skid plate. I was able to lose over 3 ½” around the middle. You could lose more! With the trend nowadays of keeping the center of gravity low, it's the only way to go! Keep in mind the need to bend t-case shifter(s), build a new skid plate, and that the rotation plate moves the transfer case ¾” to the rear. Depending on your driveshaft yoke positions and length, you may have to lengthen the front and shorten the rear accordingly. Also, instead of filling the t-case up to the bottom of the fill plug, remove the upper right bolt from the front output shaft rear bearing retainer and use that as your gear oil level indicator. If you don't, you'll blow oil out the vent in no time!

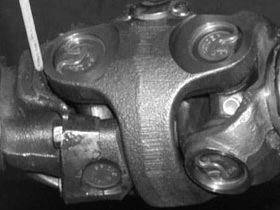

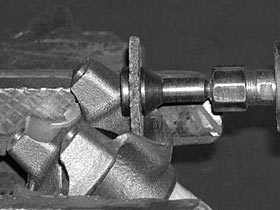

Note: I know quite a few people who have rotated their Dana 300 t-cases by re-drilling the mounting holes for the new location. While they have been successful so far, I would be very leery of this practice, especially if you're fond of that skinny pedal on the right. The Dana 300 case has strengthening bosses built into it in the standard location of the mounting bolts for a reason. Drilling into the area adjacent to the bosses would greatly reduce the strength of the case. This has to affect durability and could lead to premature failures. Installation Procedures: The installation instructions from Onetime 4X4 are adequate if you are familiar with the mechanics and nomenclature of the Dana 300 transfer case. However, if you're like me, pictures are worth many thousands of words! Fortunately, the folks at JB Conversions have gone the extra mile to include extremely detailed instructions with lots of photos for all of their components, including the Big Shaft Kit, which they sell for Onetime 4X4. Just take a look at their website, www.jbconversions.com. All installation instructions and photos are shown there in full color. If you still have any questions, feel free to send them an email. They are always extremely helpful. Other Considerations: Both the JB Conversions & Onetime 4X4 output shafts come with 1310 CV style yokes, which fit most applications. However, if you're still running non-CV drive shafts like me, simply call Tom Wood's Custom Drive Shafts at 1-877-4XSHAFT, or email him at www.4xshaft.com. He can send you a conversion U-bolt kit (his part number ‘3R') that allows the use of standard 1310 u-joints with CV style yokes. Of course, he would also be happy to send you a custom driveshaft specifically for your application, as well! Tom was also kind enough to point out that either way, CV style yokes limit allowable drive shaft angles, unless properly “clearanced.” He sent along the following photos showing the “why” and the “how.”

Tom stated that if done according to these photos, the reduction in yoke strength will be insignificant - especially compared to the benefits. I set mine up in the vise just like in the photo and took my sweet time, starting by carefully removing the greatest portion of metal with my 4 ½” grinder. I then switched to my air grinder to smooth everything out and finish the job. I've seen what can happen when a drive shaft gets in a bind. The results aren't pretty - one Dana 44 differential pinion shaft and one cracked aluminum transfer case!

In my case, I had to modify both drive shafts to make these upgrades, because the CV style yokes are longer than stock, non-CV yokes. If I hadn't already had a another manufacturer's rotation ring installed previously, the increased length of the CV yokes would have worked just fine because of the extra ¾” width of the JB Conversions rotation plate, as mentioned previously. If you are using long-travel slip yokes, you may not need to make drive shaft modifications at all. The Cost:

You may have additional cost to modify driveshaft(s), but you would probably still have that cost with a different t-case. The truth is that with a little time and effort, you can save yourself lots of money that you can use for other things, like bigger tires and bigger axles. Plus, you have the option of adding an E-Brake (about $500) if you like, that you wouldn't have otherwise! The Results:

Big tires + Big Engine + Big Rocks = Rockcrawler.com!

|

|||||||||||||||||

|

Help spread the ROCKCRAWLER world!

Share on Facebook

|