|

|

|||||||||||

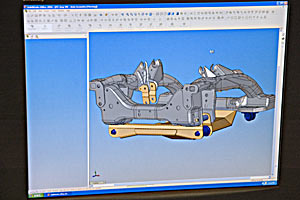

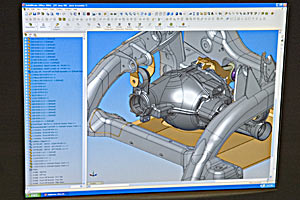

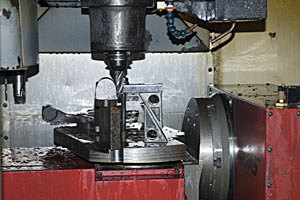

| How exactly did things change, anyway? Well, Bret and Kevin had plenty to show me back at Superlift HQ. Kevin showed me CAD drawings of the new Grand Cherokee/Commander suspension at Metalforms. It was amazing to see how he was able to manipulate parts and examine gaps between them in three dimensions. He demonstrated to me how the cradle was designed to hug the underside of the differential as closely as possible, while still leaving enough room for parts to breathe and not interfere with each other. It was absolutely amazing. He was also able to show me, for example, how the Superlift knuckles compared to stock knuckles. Superlift uses this high technology to design and manufacture their kits to the highest standards. In the manufacturing building Bret showed me how the computer designs were put to use. In a bin were a bunch of Grand Cherokee knuckles that had just been cast. While the stock knuckles are made of aluminum, Superlift chose to use cast iron for theirs because the neck of the knuckle has to be much longer. The knuckle would also be put to more extreme use, so cast iron was thought to be a better choice, despite the considerable weight gain. The knuckles were being put through the paces in one of several CNC machines. These awesome machines were computer-programmed to perfectly drill holes, machine, polish and more. The operator simply put the right tooling in and punched up the program on the computer. The machine did the rest all by itself and out came a gorgeous knuckle - ready to use. Not far from the CNC machines were two massive laser cutters. Once again, computer designs are sent to a cutter, where a large piece of sheet metal sat ready to be turned into plates and brackets. The laser would cut each part out with absolute precision with minimal waste. Each piece that was cut was cool to the touch and perfectly cut, with no need for filing or buffing. Absolutely amazing stuff to watch. All bending is done further down the line, where a worker was good enough to give me a demonstration on the press brake. The hydraulic brake is set up specifically for each part being bent and they are done in batches, so every part comes out the same. A simple push of a foot pedal and the brake puts each bend into the metal, one at a time. Once all the parts are cut out and bent, workers hand-weld and finish them. They are then sent out for powdercoating, returned, and packed for shipping. Every part, bag of parts, or box of parts is weighed several times before shipping. Using known individual weights, the shipping department can know very accurately if even a small part is missing on a loaded up pallet. If the weight is wrong, the whole pallet has to be torn down to find the missing or extra part. This helps to reduce missing parts at every level from distributor to dealer to customer. So after wowing me with the grande tour, I wanted to see more. I wanted to see the super secret new stuff. You know, show me to the SkunkWerx. And show me they did! Boy are these guys pushovers! |

|||||||||||

|