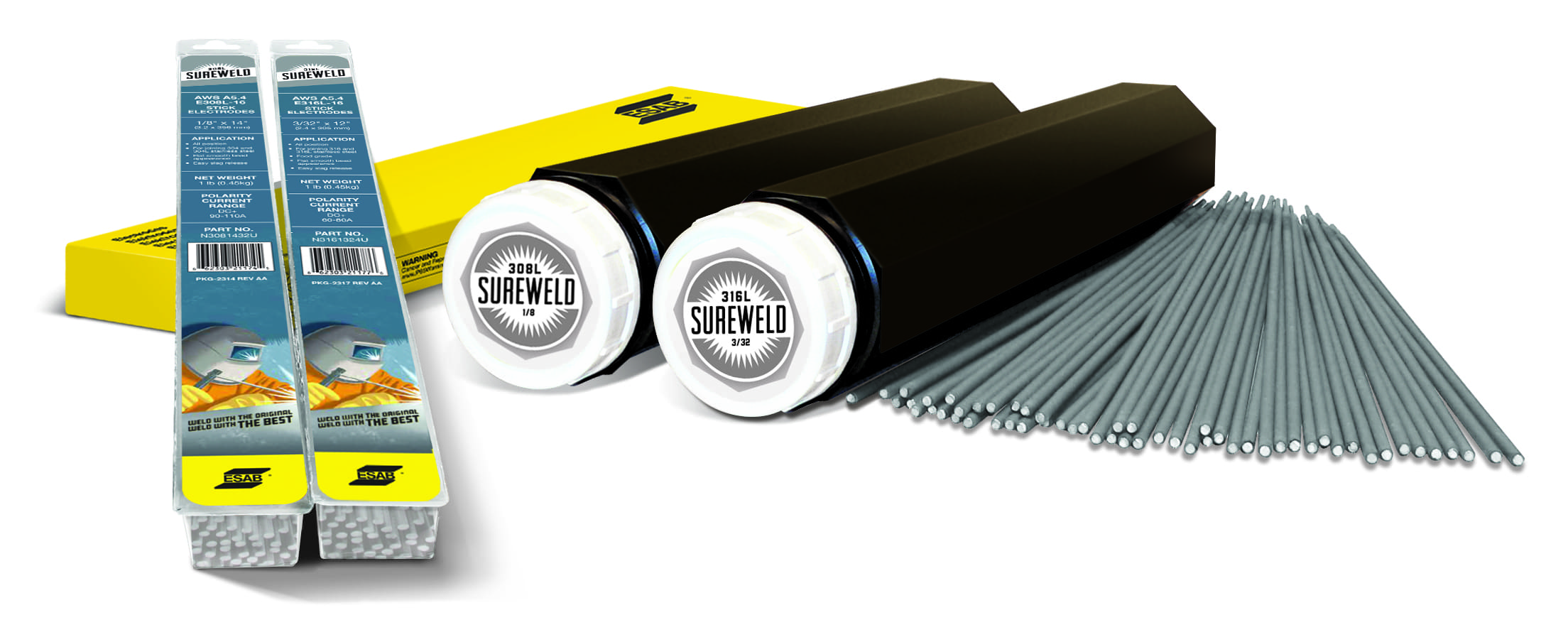

Annapolis Junction, Md. – ESAB Welding & Cutting Products has transformed its Sureweld brand of Stick welding electrodes to meet the needs of retail customers. The company has expanded the number of grades available and packaged the 3/32- and 1/8-in. diameter electrodes in 1- and 5-lb. resealable plastic tubes.

Sureweld carbon steel electrodes grades include 7018, 6010, 6011, 6013, 7014 and 7024; stainless steel grades available include 308L, 309L, 316L and 312. These grades are available in 5/32-in. diameter, 5-lb. packages as well. ESAB also offers retail packaging for Sureweld 55 Cast for cast iron repair and will introduce a 4043 aluminum electrode later in Q3.

“The Sureweld portfolio meets the needs of professional and occasional welders who use smaller quantities of particular electrode grade or who want to use factory-fresh electrodes when starting a new project,” says Halinson Campos, Product Business Manager – Filler Metals, ESAB. “The 1/8-in. diameter is the most popular electrode in the world and many applications require one pound or less of electrodes, so we wanted to align our new packaging with the way welders work.”

The new packaging includes new color-coded identification and retail displays to help distributors and customers select the proper product. Reasonably-priced Sureweld electrodes are formulated to meet AWS guidelines and are manufactured in Monterrey, Mexico, enabling ESAB to control quality and consistency when ensuring reliable availability. Sureweld 7018 electrodes are designed to produce X-ray quality welds, while Sureweld 6011 electrodes are ABS (American Bureau of Shipping) approved.

“The Sureweld portfolio meets the needs of every common Stick welding application,” says Campos. “Sureweld electrodes are an excellent complement to ESAB’s new MiniArc Rogue Stick welder, an 18-lb. inverter that offers the industry’s best combination of power, performance and affordability.” To showcase the connection, ESAB is giving away a free 5-lb. sample package of Sureweld electrodes with every Rogue purchase; visit esab.com/roguepromo for details.

Electrode Innovator

ESAB founder Oscar Kjellberg, a ship engineer, invented the world’s first Stick electrode in 1907 to solve contamination and embrittlement issues in ship building, laying the foundations of modern welding. Today, ESAB offers an industry-leading Stick electrode portfolio for welding and hardfacing, as well as its Exaton™ brand for challenging stainless steel and nickel alloy applications. It’s Atom Arc® 7018, Atom Arc 7018 Acclaim and Sureweld 10P/10P Plus are made from domestic steel cores at ESAB’s Hanover, Pa., filler metal facility and meet Buy America requirements.

Last year, ESAB launched its ESAB 7018-1 Prime low-hydrogen Stick electrodes (AWS E7018-1 H4R) in the U.S. market. ESAB 7018-1 Prime comes in a 24-lb. master carton that contains six VacPac™ vacuum-sealed packages.

“The VacPac contains 4 lbs. of electrodes because the average welder in an industrial operation consumes 3 to 5 lbs. of electrodes per shift,” notes Campos. “Compared to the industry’s standard 50-lb. cans, VacPac reduces or eliminates the need to scrap unused electrodes at the end of the day or re-bake them in a rod oven. Four-pound packages are also much easier for operators to carry and less expensive to ship.”

At ESAB, we exist to shape the future of welding and cutting. We connect fabricators with the widest range of products under our industry-leading brand portfolio with the latest technologies to solve virtually any industry challenge — then we back it up with our knowledge, experience and passion to help them be more productive than ever before. To learn more, visit esab.com or call 1-800-ESAB-123.