|

Adding the

Front Locker

If

you have any other questions about the locker, feel free to send

me a personal

email. Also don't hesitate to contact Powertrax

or your local Powertrax dealer for application information. The

Powertrax No-Slip has been manufactured to fit many rear ends, including

some limited slip applications. If

you have any other questions about the locker, feel free to send

me a personal

email. Also don't hesitate to contact Powertrax

or your local Powertrax dealer for application information. The

Powertrax No-Slip has been manufactured to fit many rear ends, including

some limited slip applications.

Shortly after

I installed the rear locker and took it out on the trail a few times,

I became addicted to traction. With each outting I found myself

attempting more and more gravity-defying feats in my moderately-equipped

TJ. There was no stopping me, and I have the dents and dings to

show for it.

Every now and

then, I'd encounter a steep rock ledge, or some kind of terrain

that my locked rear axle was unable to push my open front axle up

on to. I'm sure all of you know what it feels like to be stopped

by terrain that you just know in your gut that you could have made

it if you had adjusted your line a little... or if you had a front

locker.

|

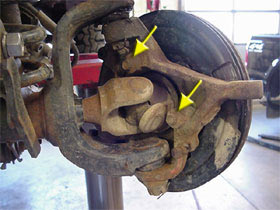

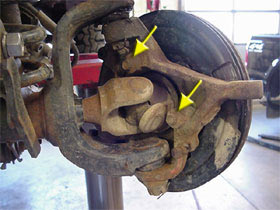

| You'll want to get

your tie rod out of the way. Unbolt it from the spindle,

give it a good smack on the knuckle with a hammer, and

the tie rod end should drop right out. |

|

Front

End Concerns:

Never having been equipped with a front locker before, I had

a couple of concerns which were as follows:

- Will

my Jeep still be tolerable as a daily driver with the addition

of the Powertrax No-Slip front locker?

- Not

being much of a mechanic, will I be able to install it myself

as easily as the rear locker?

My questions

were answered soon enough, because my locker was on the way,

whether I was ready to tackle it or not. First, I combed the

web for answers to these two questions. They were answered,

but not to my satisfaction. After some searching, did manage

to piece together enough information about the install.

|

From the information

I pieced together, I found out that most people had tried to install

front spider gear replacement lockers on late-model Jeep Wranglers,

and they had encountered a problem where the cross shaft interfered

with the ring gear. This means the ring gear needed to be removed

to complete the installation successfully, which also meant that

the whole carrier must be removed from the housing.

|

Remove

the Diff. Cover and Inspect

The first thing that needed to be done after the tie rod was

hanging out of the way, was to move the differential cover

and examine my setup. That would tell me exactly what I was

in for in an instant.

I did

just that, and after admiring the apparent dirtiness of my

gear oil, I turned the carrier and noticed that, indeed, the

removal of the cross shaft would be obstructed by my ring

gear.

Again,

this is a 1999 Jeep Wrangler TJ with a stock 3.73 gear ratio.

The ring gear is too thick and impedes progress.

Now that

I removed the differential cover, I knew what had to be done,

so it was time to slide the axle shafts out. This is necessary

in order to remove the entire carrier, and to install the

locker. Once the locker is installed, and the carrier re-installed,

the axle shafts can be slid back in.

|

|

| You can see the

problem as clear as day in this picture. For those who

don't know what youre looking at, this is the ring gear

on the carrier behind the differential cover. The circle

in the center is the cross shaft which needs to come out

to install the locker. As you can see, the teeth on the

ring gear block it from sliding out. |

|

|

| Brake calipers are

hanging out of the way and we're one step away from sliding

the axles out. |

|

The first

step to sliding the axles out would be to disconnect the brake

calipers. You don't need to disconnect any brake lines, just

unbolt the calipers from the rotors. Just a quick warning

- be very careful to not cross-thread the caliper bolts when

putting them back in later (what a pain in the butt that was)!

Hang the

calipers out of the way using a wire or bungee cords. Once

that is done, the rotors should be able to slide off easily.

Put them down on the floor.

Also,

don't let anyone accidentally press your brake pedal while

the calipers are off the rotors. If they're left alone, they

should slide back on over the rotors easily when you are done.

|

|

| Two of the three

bolts needed to disconnect the axle shaft assembly from

the spindle can be seen above. |

|

|

| In the picture above,

the rotor and shield are still attached - this is not

necessary. |

|

Remove the

Axles

On the back of the spindle, there are three bolts around the axle

u-joint. You can see two of them in the picture above and to the

left. The third is obscured on the other side of the axle shaft.

These three bolts attached the sealed wheel bearing assembly to

the spindle. The axle is secured to the wheel bearing assembly,

so when the bolts are removed, you can slide the whole assembly

out in one piece.

|

| The axles are removed

from each side. It is possible that your axle tubes are

very dirty on the inside. I recommend cleaning them out

thoroughly before re-installing. |

|

|

| Inside the rear,

on the left and the right side, you can see the bearing

caps. These must come off, but you must remember their

exact position to ensure proper wear. |

|

Pull the

Carrier

Once the axles are out of the way, you're ready to pull the carrier

out of the housing and set it on the bench. This is the only really

critical step that I was instructed to pay close attention to. On

the inside of the differential, on the left and right side, there

are two arcs that are bolted down. These are bearing caps. You need

to remember how they are positioned when you remove them so you

can re-assemble them the same way.

By re-installing

them in the same position they were un-installed, you ensure that

you are not changing any tolerances that would affect how the bearing

wears underneath. Mark them and put them in a safe place while you

work.

When the bearing

caps are removed, the carrier will most-likely roll right out. If

it resists, you may have to pry it out with a pry bar, in which

case, be careful not to damage anything. The carrier is the assembly

on which the ring gear is mounted and the spider gears are contained

within. On each end there will be a race that seats a bearing. Pull

off each race. Again, keep track of their position so they get put

back in the same position.

|

Tearing

Down the Carrier

At this point, we're done working under the Jeep and we can

continue our work on the bench. The carrier in which we install

the Powertrax No-Slip is now seperate from the vehicle. Next,

we unbolted the ring gear by securing the carrier in a bench

vice and turning each bolt out one by one. You'll need your

Popeye arm for this. Once each bolt was out, we marked where

the ring gear was seated on the carrier so we could put it

back the same way.

The ring

gear wasn't bolted down, however, it is still tightly seated

on the carrier. It took some prying to remove it. Once we

had it off, we cleaned it and set it aside.

Now it

was time to remove the spider gears. This was the last thing

we had to dis-assemble before we could begin re-assembly with

the Powertrax No-Slip.

|

|

| Pictured here is

the carrier with the ring gear still on it. Also, a hammer,

a punch, and the roll pin that holds the cross shaft in

can be seen here. The roll pin is out and between the

punch and the hammer. |

|

|

| An empty Dana 30

carrier awaiting the installation of a Powertrax No-Slip

Traction System. |

|

The roll

pin caught us off-guard. I had been used to working on my

Dana 35, which uses a retaining bolt to hold the cross shaft

in, not a roll pin. Not having worked with it before, I didn't

know exactly how it liked to come out, nor did I know how

much force to exert on it.

I tracked

down the proper tools, pictured above, and tapped it out with

only very mild force. Once the roll pin or retaining bolt

is out, the spider gears practically tumble right out.

Take the

old cross shaft, spider gears, side gears, and all related

thrust washers and put them in a box and take them with you

to your next swap meet. Who knows, someone might need them

on the trail. You won't need to re-install them.

|

Page

3 (Install and Test the Powertrax) --->>>

|

If

you have any other questions about the locker, feel free to send

me a

If

you have any other questions about the locker, feel free to send

me a