|

No-Slip

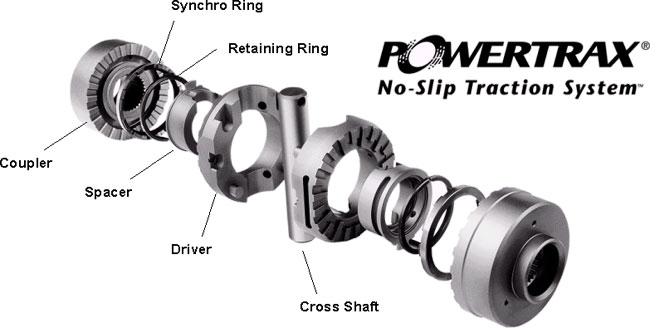

Traction System - Operation-Summary The Powertrax No-Slip Traction System is the only differential that offers the maximum traction performance of a locking differential with the smoothness of a limited-slip/posi differential. It delivers power to both wheels through intermeshing teeth in such a way that one wheel cannot be powered ahead of the other. A specially contoured saddle ensures direct engagement of the intermeshing teeth. The No-Slip Traction System features a precision synchronization mechanism that holds the driver and coupler disengaged throughout a turn, so the unit remains quiet and operates smoothly. In addition, the springs mounted in the saddle (that impinge on the pinion cross shaft) and the turning resistance of the synchronization mechanism help damp out backlash effects. As a result, the No-Slip Traction System's operation is virtually unnoticeable to the vehicle driver until its extreme traction performance is required.

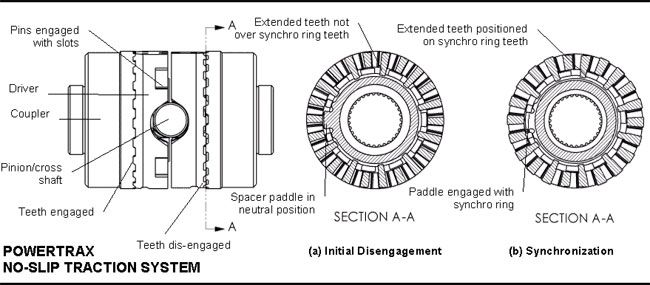

The figure below illustrates the operation of the precision synchronization mechanism. In the figure the Powertrax No-Slip Traction System driver disengages to allow wheel differentiation, the synchro ring rotates with the coupler and the teeth of the synchro ring travel under the extended teeth of the driver. The synchro ring continues to rotate with the coupler until it contacts the spacer paddle. The spacer paddle then stops the synchro ring, thereby controlling the specific amount of overlap of the synchro ring teeth relative to the extended teeth of the driver. The overlap position of the synchro ring prohibits the driver teeth from reengaging with the coupler teeth. As the coupler continues to rotate through the turn, the driver is held disengaged from the coupler and the coupler teeth are able to spin freely over the driver teeth. This precision operation eliminates the common ratcheting sounds and harsh characteristics associated with other locking differentials. After the vehicle comes out of the turn, the speed of the two wheels equalize and a slight rotation of the coupler in the opposite direction carries the synchro ring out from under the extended teeth of the driver, thereby allowing the driver and coupler to fully reengage and connect the two axles together again. The result is maximum traction, full differentiation, smooth action and quiet operation.

Figure - A precision synchronization mechanism controls engagement and keeps intermeshing teeth disengaged for quiet turns and smooth operation. The springs in the saddle of the driver help cushion backlash. When the vehicle is under power, the driveline acts as a large torsion spring. When power is relieved, the driveline travels backwards moving the cross-shaft from the front side of the saddle to the back-side of the saddle. The springs in the saddle slow the cross-shaft travel and cushion its contact with the saddle, making the operation considerably quieter. Frictional resistance between the retaining ring (nested within the synchronization ring) and the coupler also helps damp backlash effects. When power is relieved while in a turn, or when just transitioning from drive to coast, the paddle turns the synchronization ring as the cross shaft moves from the front to the back of the saddle. The frictional resistance of the retaining rings works to absorb the elastic energy in the driveline and, together with the saddle springs, helps eliminate driveline resonance. The Powertrax No-Slip Traction System offers a superior combination of maximum traction, smooth and quiet operation, plus easy installation within the existing differential case. Other differentials require the entire differential case be replaced and expensive new bearings press fitted onto the case. Consequently, the ring and pinion gears that drive the case require exact realignment performed only by professionally trained driveline mechanics. Conversely, because the No-Slip Traction System easily installs in the existing case without disturbing the critical setup of the ring and pinion gears, even the do-it-yourselfer can install the device, in about an hour, without any previous experience or special tools. Since it can be easily installed by the do-it-yourselfer, any mechanic, at any type of service facility, can also install the Powertrax No-Slip Traction System. The strength, durability and reliability of the Powertrax No-Slip Traction System have all been perfected. ZytaniumÔ cross-shafts are 50% stronger than the originals and are included within every model. Geometries of the saddle and the intermeshing teeth profiles have been optimized to maximize both engagement strength and torque transfer output. An increase of 20% in power transferring teeth contact was achieved for non-C-Clip models and an increase of over 40% for C-Clip models. All C-clip models maintain tooth continuity throughout to preserve tooth pattern symmetry and to maximize strength. The Powertrax No-Slip Traction System incorporates an internal access slot for effectively installing the C-clip without the need for teeth elimination that adversely reduces traction output levels. Overall design results allow the Powertrax No-Slip Traction System models to withstand over 6,800 ft-lb of torque per axle for very small differential applications (representing 75% more torque capability than the axles themselves), to well over 35,000 ft-lb for large differential applications (representing up to 250% more torque capability than the axles themselves).

|