| Back to Features Page By, CHAD CROWELL

|

|

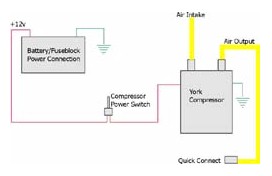

| York Air Install for Jeep TJ Go to a junkyard. Sure, the Yorks are available new from some places, but I rooted around in a junkyard for a half an hour before finding my donor; a 1974 Volvo 110. The York was sitting pretty with a stout bracket and long hoses that were in good shape. Ford used Yorks under the Motorcraft label, but also changed the model numbers, so it's harder to figure out which York you are getting. Older AMC and Volvo cars are your best bets to find one. I walked away with mine for $35. What to Look For The York is a rectangular unit with an octagonal top section. It is cast steel and should be easy to identify by its unique shape. It will have two hoses sticking out of the top in a variety of possible configurations. The best seems to be the AMC or Volvo style, where the hoses run away from the compressor at a right angle, rather than the Ford style, where they loop up and over, requiring more hood clearance. You will see a metal tag on the front of the unit that says YORK and has a few numbers on it. Look for a number with a sequence similar to "F209R". This tells stroke length and discharge direction. The "09" in the above number represents a 9" stroke length, and 07 and 10 can be found, 07 being shorter length and 10 longer. The longer the stroke length, the more air is pumped per revolution. Discharge direction is not of much consequence. If the tag is not readable, removed, or it is a Motorcraft, you can also check the stroke length by removing the clutch and looking at the crankshaft. To do this:

The optimal number is XX10R or XX10L, which will give the highest CFM output. Mine is the "09" medium version, but the compressor was in such good physical condition that I decided to go with it. The output is definitely enough for my needs. Be sure to cut the input/output hoses as far from the York as possible. Keep the mounting bracket and grab some idler pulleys off a few cars while you are there. Before you leave, test the unit by placing a thumb over the output and turning the pulley. Release your thumb and see if pressure has built up. You should feel a burp of air and hear it as the pressure releases. Also hook the wire exiting the compressor to a battery and ground the chassis, you should hear the magnetic clutch engage and disengage as you apply and remove 12V from the wire.

That should help you get started on your very own York compressor installation. The great part, for you out there who don't own a TJ, is that none of this is vehicle-specific. Next month, the York will be installed along with accessories that will help you get more out of your air compressor system.

Some information courtesy of the Jeep Tech pages. |

|