|

|

|

| |

| This

is the first of three features (read

Part II) that will focus on the Atlas II Transfer Case,

manufactured by Advance

Adapters. This feature will take a look at the advantages,

disadvantages, and reasoning behind choosing to install an Atlas

II in a moderately configured Jeep Wrangler TJ. The following

features will delve into the installation of the unit, and finally,

we will evaluate its performance on both road and trail. |

|

The

Holy Grail

The

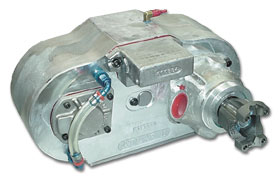

Atlas II Transfer Case has come to be the "Holy

Grail" of performance transfer cases for recreational,

and competition four-wheelers. The gear-driven Atlas

II boasts superior strength and either 3.0:1, 3.8:1 or 4.33:1

gear reduction. Twin stick operation allows individual

control of front and rear axles on the trail. These

features, and more, help make the Atlas II Transfer

Case a favorite among serious four wheel drive enthusiasts. |

|

| We

chose the Atlas II for our application because it offers

exceptional strength, improved gear reduction, and individual

axle control. While other transfer case upgrade options

may be more cost-effective, the Atlas packs in a much

more comprehensive set of features in a new and ready-to-install

package.

The

case itself is a rock-solid, one piece design, machined

from 356-T6 Heat Treated Aluminum Alloy. The Atlas II

is 2.5 inches shorter than an NP231 with a short shaft

conversion kit. This will allow us to run a longer rear

driveshaft, and further reduce the potential for driveline

vibrations. Our transfer case is going to be equipped

with a 32 spline front output shaft and a stronger yoke,

which is common for 1/2 ton and 3/4 ton trucks. This

feature can be identified by a blue anodized front output

seal retainer.

| Final

Crawl Ratio Comparison * |

| 1999

TJ with NP231 |

TJ with Atlas II |

| 38.86:1 |

61.86:1 |

| AX-15,

3.73 |

AX-15,

3.73 |

|

|

|

|

|

Equipment

Our

Atlas II is going to be mated to an AX-15 manual transmission

in a 1999 Jeep Wrangler, thus, it will be configured

with a left-hand drop, 4.33:1 reduction, a 23 spline

input, and a CV-1310 rear output. This setup typically

retails for around $2,400.00. In addition, we will be

adding a 32 spline front output with a CV-1310 yoke,

which adds another $300 to the total.

The

Atlas II will be replacing an NP231 Transfer Case equipped

with a Tom Wood Short Shaft Conversion. The NP231 is

a cast aluminum, two piece design, that has a low range

ratio of 2.72:1, and is chain driven as opposed to gear

driven. While the NP231 has proven dependable, it is

by no means bulletproof, and does not offer nearly as

much peace of mind as the Atlas II.

The

recipient TJ is equipped with approximately 2.75"

of suspension lift, 32" tires, and original 3.73

gears housed in Dana 30 and Dana 35c axles. The Atlas

II will be providing more than enough strength for this

application and will help provide a competitive crawl

ratio. Perhaps overkill for this vehicle configuration,

the Atlas II offers strength, performance, and room

to grow. If the hefty price tag fits within your budget,

you will likely be purchasing the last transfer case

you will ever need. |

|

| Gear

Reduction

The

primary feature that drew us to the Atlas II Transfer

Case is the 4.33:1 low range ratio. Our moderately-equipped

Jeep Wrangler is a relatively comfortable daily driver

with great high range gearing for all pavement conditions.

We do not plan on performing a ring and pinion swap

as long as the vehicle is equipped with 32" tires.

The Atlas II will allow us to keep the good street gearing,

but it will help provide a much-improved crawl ratio

for technical terrain.

Currently,

the NP231 with our transmission, and differential gear

ratio provides an ultimate crawl ratio of 39.86:1. Enter

oversize tires into the equation and this ratio can

quickly become inadequate. In terrain like that pictured

on the right, being able to effectively control your

slow speed is almost mandatory.

Not

being able to go slowly and carefully can result in

catastrophic damage. On the other hand, too much use

of the clutch in such a situation might result in temporary,

or permanent clutch failure. One needs to be able to

keep the speed to an absolute minimum with little, or

preferably no use of the clutch.

With

proper low gearing for extreme terrain, the driver can

pay more attention to steering and watching the spotter,

and pay less attention to speed control and keeping

the engine alive. Our Atlas II will provide us with

an ultimate crawl ratio of 62:1, which brings us closer

to blissful rockcrawling. While 62:1 isn't "extreme

granny" by today's standards, it is very good,

and considerably better than stock. |

|

|

Photo:

Michael McCready

|

Strength

Overall

strength is the other feature that makes the Atlas II

transfer case so appealing.

The

cast aluminum split case design is no doubt the weakest

characteristic of the NP231 transfer case. A common

problem that many older NP231 transfer cases experience

is a cracked housing, which can mainly be attributed

to fatigue. These transfer cases can also easily be

destroyed by the front axle being rammed with exceptional

force. As a result, the front driveshaft over-compresses

and breaks through the front output section of the transfer

case. General internal failure, although uncommon, can

also cause an NP231 to be blown apart, as shown in the

picture on the left.

The

rock solid Atlas II transfer case weighs in at 110 lbs

(dry), which is approximately 40 lbs heavier than the

NP231. The case isn't just strong on the outside, though.

The internal workings of the Atlas II are complimented

by large helical-cut gears, and an assortment of heavy

duty components. Most chains, in chain-driven transfer

cases, are prone to stretching out over time, but this

gear-driven alternative will likely last forever.

The

Atlas II is built to be used and can easily cope with

the rigors of serious four-wheeling.

Continued

--->>> |

|

|

|