Jeep really nailed it right on the head when they released the Wrangler Rubicon. With dual lockers, Dana 44 axles at both ends, 31″ tires and more, there is little more that a Jeeper could want from an out-of-the-box rig.

Jeep really nailed it right on the head when they released the Wrangler Rubicon. With dual lockers, Dana 44 axles at both ends, 31″ tires and more, there is little more that a Jeeper could want from an out-of-the-box rig.

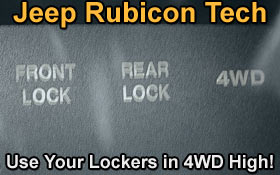

One area where the Jeep Rubicon does fall just a bit short, however, is the way the lockers are set up to work. Most-likely designed the way they are for safety and liability reasons, the lockers only function when the transfer case is low range.

Who cares, right? If you are sitting there asking that, then perhaps you’ve never been mired in a mud bog, been on a snow run, or hit the sands of Glamis. In these, and certainly other situations, low range just isn’t going to cut it. You need 4WD high or you’re stuck. Therein lies the rub.

So there you are, stuck on a sand dune, nailing it with all you’ve got and you’re doing nothing but watching your fronttire sit still and maybe once in a while catch a little traction. Meanwhile, the rear is catching a bit now and then, thanks to the limited slip in the Rubicon, but it’s still not grabbing on like the real locker would. Oh, if only you could turn on those blasted lockers!

Well, don’t tell your service writer this, but a few Jeepers got their thinking caps on and put their eyes on the Jeepservice manual schematics long enough to figure out how to trick the computer into letting him use his lockers in high range. There are several ways of doing it, and Bill Snowden (Willie G) chose the method shown here. Follow the easy steps below and you’ll be well on your way to locking ’em up, too.

But first – a little disclaimer. Obviously, if you don’t know what you’re doing, don’t do the modification. Also, we canshow it to you, but we haven’t tried it ourselves here at RC HQ and we certainly won’t be held responsible for showing you kids how or telling you to do it. Using lockers in high range, especially on the road, can be very dangerous, which is why the good folks at Jeep wired them the way they did. So do the modification at your own descretion, be careful, and if you goof something up, don’t blame us. If you choose to try this yourself, you assume all risk associated with the use of any information contained within this article. And don’t be surprised if your service writer figures out what you’ve done and says no to your next warranty claim. That said, read on…

As with most electrical installations, the first thing you’ll need to do is disconnect your battery. Then disassemble part of your dash. Begin by prying up the defroster vent panel by the windshield. You can use a flathead screwdrive or, like Bill, you can pick up a real trim tool from your Jeep dealer for about $3. Pry the trim in several places along until it pops out.

Once the vent is out of the way, you will see two Phillips head screws. Remove these, and this will allow the center dash bezel to be carefully pulled off by pulling straight out and upward.

The HVAC controls and the switch panel will be exposed. There are four screws that hold the switch panel in place,. Remove them and pull the panel out of the dash. In the photos here, you’ll see the toggle switch for the lockers already installed. Bill chose to use an aircraft-style switch with a safety cover to activate the locker bypass. The switch used in this install is an inexpensive $10 switch. If you go topless and/or doorless often, we’d recommend using a military-spec switch. They are dust and moisture-proof and they do cost more, but they are worth it in the long run. You can get these from Kilby Enterprises.

The HVAC controls and the switch panel will be exposed. There are four screws that hold the switch panel in place,. Remove them and pull the panel out of the dash. In the photos here, you’ll see the toggle switch for the lockers already installed. Bill chose to use an aircraft-style switch with a safety cover to activate the locker bypass. The switch used in this install is an inexpensive $10 switch. If you go topless and/or doorless often, we’d recommend using a military-spec switch. They are dust and moisture-proof and they do cost more, but they are worth it in the long run. You can get these from Kilby Enterprises.

Looking at the back of the toggle switch, there is a red wire with a white stripe. If this wire is connected to the vehicle ground, it tells the computer that the transfer case is in low range. The computer will then allow the lockers to engage, as long as the vehicle is going less than 10 mph. The object of the modification is to trick the computer into thinking the transfer case is in low range, in order to allow the lockers to be turned on.

Take a piece of wire and tap into the red/white striped wire, and run this to your switch. Then tap into the black wire and run that to other pole on the switch. When the switch is turned ON you will be able to use the lockers in any transfer case range. With the switch in the OFF position, the lockers operate in low range only.

The safety toggle switch was used in order to prevent accidental use of the modification. Although any switch will work, or no switch at all, we do recommend this type of switch for the safest installation. See the chart above for other wiring options. The photos below should help you with the wiring. Click each one for a larger view.

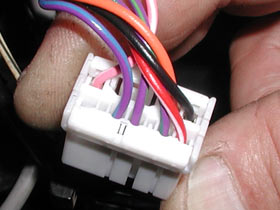

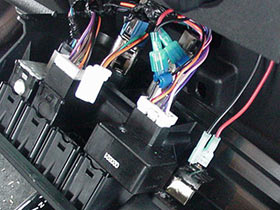

Here you can see the red/white and black wires. |

Wires clipped on to stock harness. |

Close-up of wires on harness. |

Switch mounted on center dash bezel. |

Put everything back together and go test your Jeep out in a safe location. That’s all there is to it!

When it comes to starting Jeep engines, the three basic elements needed are air, spark, and fuel. There are a variety of issues that can affect whether or not your rig cranks including heat, cold, fluids, and wear and tear on Jeep parts and cables.

When it comes to starting Jeep engines, the three basic elements needed are air, spark, and fuel. There are a variety of issues that can affect whether or not your rig cranks including heat, cold, fluids, and wear and tear on Jeep parts and cables.