This site earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

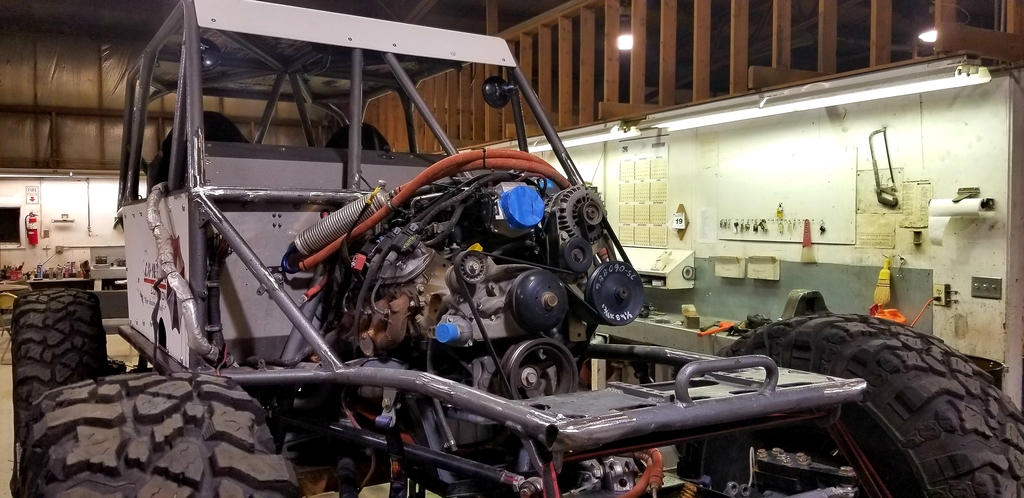

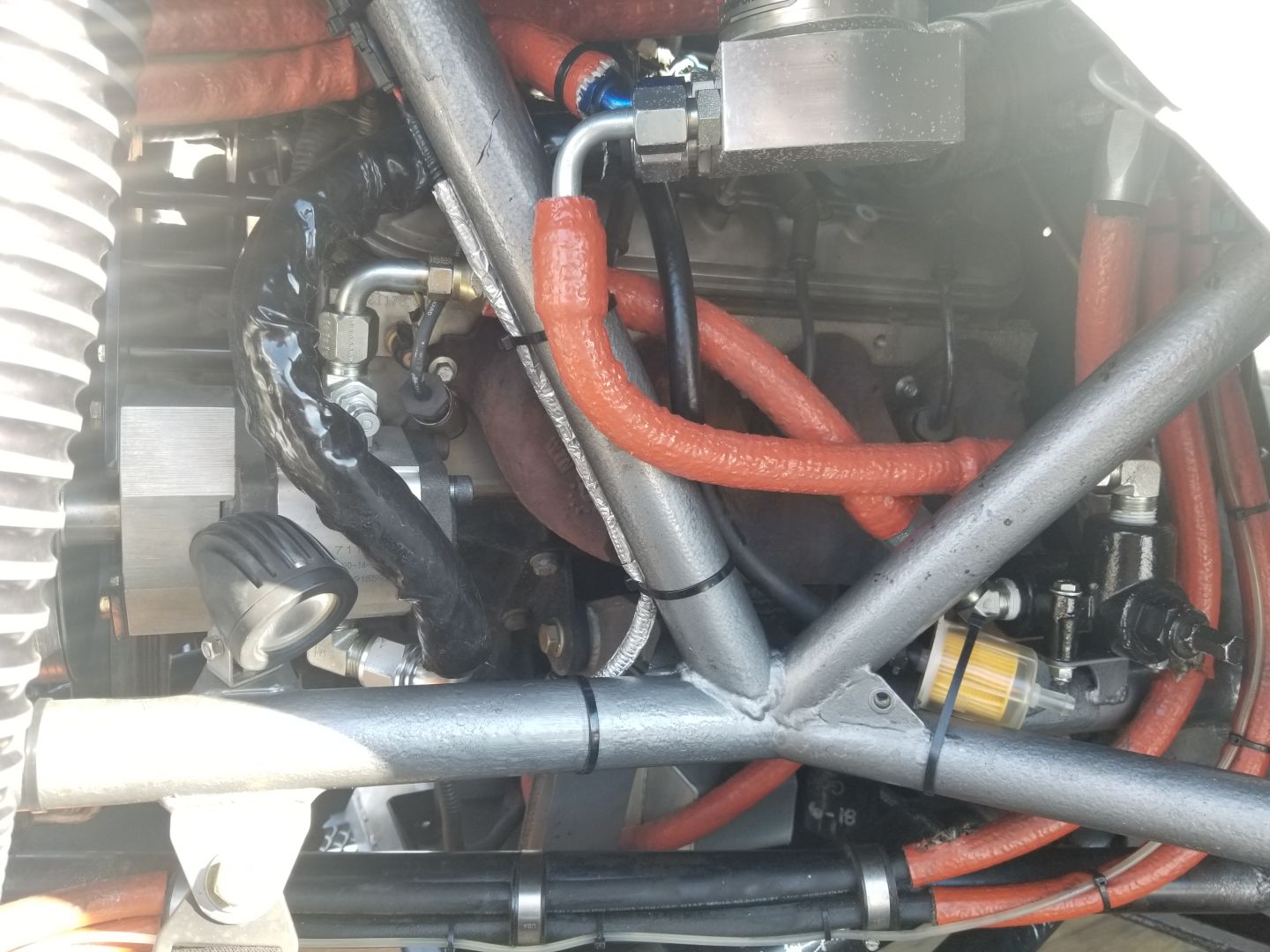

Time to update this. I built a shaved rear steer 14 bolt with a slightly offset pinion so both inner shaft end up being the same length for easier spare. Used a single ended cylinder since it is stronger than the comparable double ended cylinder of similar size. Used dana 70 Cs and 60 solid knuckles and some dually hubs I converted to SRW.

more rear steer install and controls

Then I redid some of the rear tube work to change from having like 9" of up travel to 6". Also changed the rear roof extension supports to take some of the boxy look out of it.

Then went ahead and cut the front tubes off and redesigned the front to fit a Twisted Customs 54" Cadillac CTS-V hood and get rid of the bent up ibex shape. Made the winch mount out of tube so running the rope down to the front axle is wide open. Radiator used GM style bushing mounts to hold it at the tank seams and is a snug fit between the shock hoops. I notched out the hoop to give the radiator cap room to be operated.

Then installed the hood so the side body lines line up with the top of the door skins. Re-skinned the buggy with some free .120" aluminum that was an old faded sign at work that was replaced. Hopefully they last longer than my old .040" and .050" skins of past that within a few years had gashed holes and sharp edges from rock scraping. Also built the skins for a fully body set which I think improves the look. Need to decide on colors and design and paint it when the weather gets warmer.

eternal noobie

Staff member

Car looks great! Well done with the changes!

do I see a lockout link mounted on the rear axle housing??

I'll be curious to how you like the DE front ram with the SE rear...I'm considering the same setup on my build. I know the SE rams tend to wander and need occasional correction, but packaging is SO much easier that way.

Thank you, I'm happy with the cosmetic change over the old setup.

Yes, I did add a rear tierod lockout in case of hydraulic failure or maybe an extended road section. Also give spare rod ends on the rig if needed.

I did the single ended cylinder with the idea of it being theoretically stronger than an equivalent double ended cylinder. With a 2.5" bore and no rod on one side and the other side only has a 1.125" rod vs a double ended being a 2.5" bore with 1.5" rod it should have more mechanical advantage. Also I don't see how it would wander any unless you have a bad seal or valve that could leak by. Maybe in a front steering with an orbital that is load reactive I could see some wandering but not on a system that locks that ports unless input is given thru the spool valve.

Have had the rig out a few times now trying out the new stuff. So far working good. Finally got the rest of the cosmetic stuff on as well for now.

Rig is working great. While the PBRs work good and way better in cold/snow, the BFGs can't be beat in the rocks.

eternal noobie

Staff member

looking great!! I haven't moved mine since June, anxious for weather to cool and get out in a few weeks

Made a handful of short day trips all summer with a few friends getting their rigs back up and running for testing then made it to Sand Hollow for a week. Everything worked really well and was fun to hit someplace new and anticipate going back again for sure. We ran TNT day and night, Nasty, Double Sammy day and night, Joint Effort, Chain Reaction, Triple 7s, Arrowhead, Dekleined, Chutes and Ladders, Front Range, The Fallen, Plan B, and The Maze. Not a ton of pictures but here's what I got.

Arrowhead:

Nasty half / 3 monkeys area:

Somewhere above Nasty Half/3monkeys:

Made a stop to scope out TNT since a few of us did it at night for the first time, made for a cool picture. Soemthing I did this year was add a dome light that could be turned on white or red and leaving it on red worked great to see your controls but not hurt your eyes.

eternal noobie

Staff member

Yeah, we have a hard time getting pics when we are out there, too much fun to be in the rig and wheeling!

Looks like you hit all the 7-10 trails, now it's time for the 11-15's

I really enjoyed Arrowhead, that was a fun trail. Next time go back and finish the 10s and maybe see about stepping up more. Definately a learning curve for these types of trails/obstacles.

Here is a short blurb of snake pit, I enjoyed it and followed Lew thru pretty well but Joe got really twisted up and bound in it. That rig is still pretty new and he is still learning how to drive it though coming from a monster truck scout he had before.

eternal noobie

Staff member

Snake Pit with rear steer is just cheating....try it with a drag axle and front leaf springs

Very true. I try not to use my rear steer unless needed most the time and I don't recall using it thru there until getting lined up to go out the exit vs digging but I think that is how Joe got so screwed up is too much playing with the rear switch.

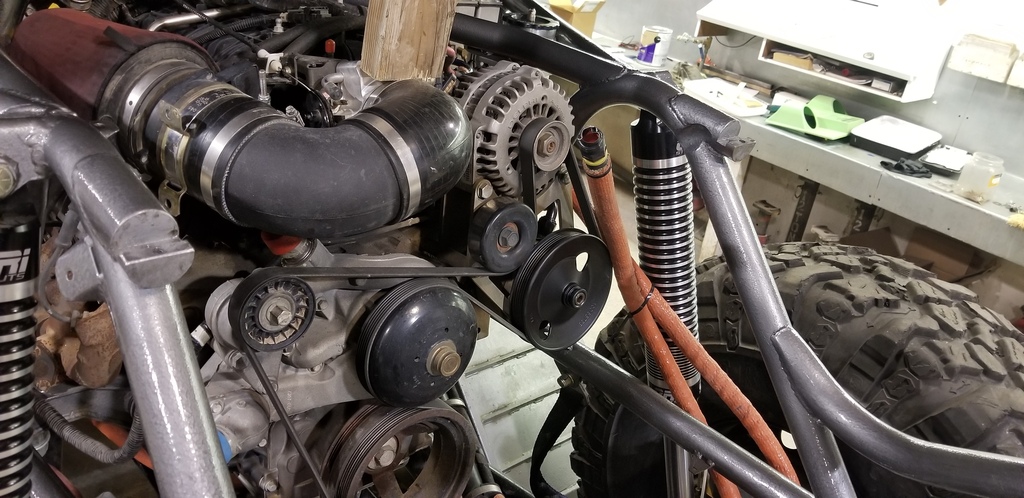

Few updates. Installed a gearpump with the load adapter from Scott's Custom Offroad. My 9 year old P pump is starting to moan after a good long day with rear steering and front water so figured was time to upgrade. Was able to re-use some of the GoatBuilt steering pump mounting plate and build a new front plate for the new pump. Seems to work good so far.

Also built front and rear push bumpers for snow wheeling. Our plan is all our rear bumpers are horizontal and roughly 36" off the ground and our fronts are all vertical. Tested them out last week and worked good. I'll see if i can post the video of a test.

Also used some lexan for a temporary front windshield and had a local upholstry shop make some vinyl side windows using my window net hardware. Worked great out snow wheeling as well.

video of the push bumpers:

eternal noobie

Staff member

Been wondering about those pumps....so far so good??

So far, yes. Only been out snow wheeling with it twice now. First time my steering did get hot to 230 degrees once but I think was because I was letting my friend run the rear steer and he might have held the swith too much which would cause the fluid to go over relief and build a ton of heat. I have watched it a bunch since then and has only gotten to around 130 degrees even after driving on a highway for 20 miles. Hope to try out in some rocks here soon along with some new tires.

Trying out the new tires. First obstacle so nothing broke in yet:

eternal noobie

Staff member

Gotta get those tires burned in

I did take them for about a 10 mile street drive at 4 psi and after that first day the edges are starting to break in but think it will take a few more trips yet though.